Loading...

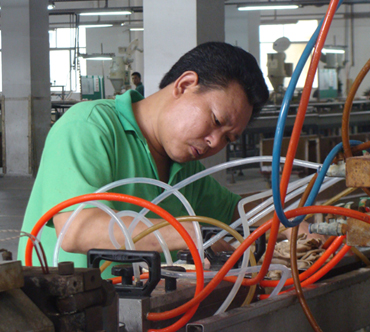

ALWA owns an Injection Molding facility in Taiwan as well as an Extrusion and assembly plant in China. In addition, ALWA has established long term relationships with more than 36 factories in the last 35 years which allows us to develop and manufacture products that range from simple components to complete electronic devices and assemblies. Our office helps facilitate relationships, production, quality, negotiations and shipping.

ALWA’s integrated approach allows our clients to enjoy the benefits of Highly Creative California Design and Engineering science coupled with low cost China and US Manufacturing.

Our product development team members are not only highly innovative creators, but are practical and cost driven as well. IDP follows a DFM (Design for Manufacturing) philosophy.

Tooling and unit cost investment along with manufacturing methodologies and efficiency are driving development factors from the beginning.

ALWA has had a manufacturing coordination office in Taiwan and China for 35 years. Our bilingual staff includes project management, engineering and quality assurance, and has an extensive network of factory relationships in a number of industries. We give clients convenience and peace of mind by ensuring production by a reputable factory and oversight by our Q/A and project management team.

US manufacturing is important to some clients. We also have a network of domestic factories that can assist you.

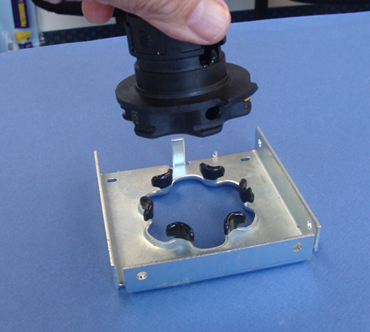

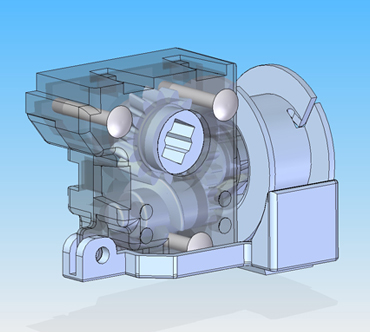

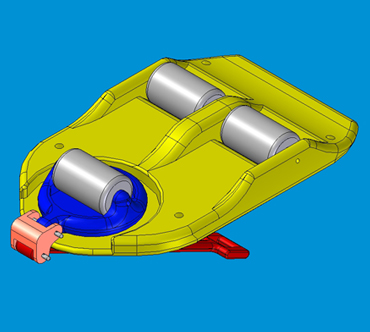

Proof of Concept, Fully Functional and Demonstration Grade Prototypes: ALWA utilizes a wide variety of prototyping techniques and tailors the process to your product’s needs. Prototyping is an essential of the product development process. This allows for proper fine tuning of the product and prove functional as well as cosmetic attributes for the final prow In between prototype stages, we work on product testing, refinement and engineering improvement. IDP fabricates custom prototypes for concept validation, marketing, fund-raising and demonstration, product refinement and to prepare for manufacturing.

What differentiates ALWA from other prototyping houses is that we are well versed in the following prototype techniques. We combine these different methodologies, as needed, to custom fabricate functional and demonstration grade prototypes.

ALWA’s expert team combines practical technical knowledge with creative, user-driven design. We know that product functionality, cost-effectiveness, ergonomic appeal and manufacturability are key to your product’s success.

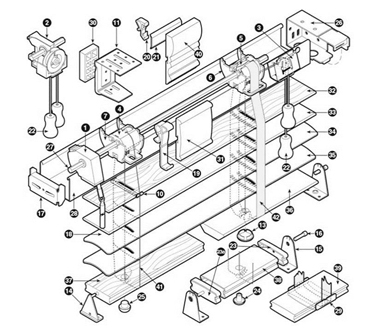

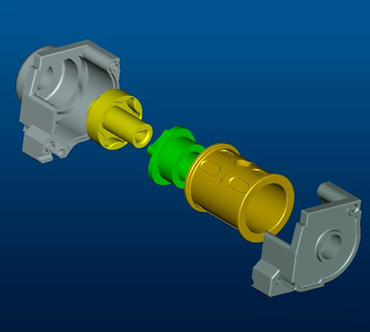

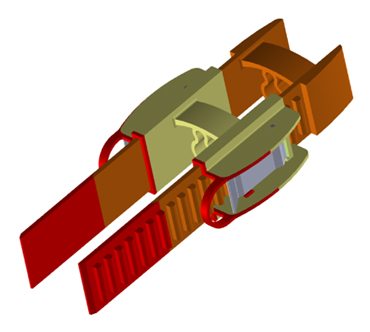

Ventana™ is the Window Covering division of ALWA Industrial, Inc. We started in the window covering industry by producing molds and manufacturing mini blind and vertical blind components for large volume fabricators in the U.S. In order to keep up with the growing demand for components, we quickly learned the importance of producing quality components that function reliably and are priced competitively.

Product design and engineering became an integral part of our company. The experience we gained in meeting high volume production requirements helped us as we expanded our product line to include 25mm mini blind components, 35mm mini blind components, 50mm High and Low profile components, vertical blind components, roller shade and roman shade components as well as ready-made aluminum, wood, and PVC blinds.

We produce components for companies throughout the world. Ventana™ window covering components are recognized as a quality supplier to world-class companies and as an innovator in the window covering industry. Our manufacturing capabilities include injection molding, tooling, metal stamping, roll forming, and extrusion. We are dedicated to producing the finest quality products at competitive prices and we have achieved this through innovative product design and efficient production methods.

By producing the components in-house, we have a great deal of control over the quality of the parts. Our experienced technicians maintain strict quality standards to insure the parts are being made to required specifications. Parts are sent to quality control stations where all critical dimensions are checked and they are assembled to insure that they perform and function according to their requirements.

Click here to visit the site.